HISTORY

The Burner Booster was Energy Efficiency Solutions’ first product in 2007, and the team has grown expand. New company expansions, startups like Advanced Burner System and in 2018 Agen Environmental Corporation would soon follow

Dear Oil Energy User/ Contractor/ Consumer:

We think you’ll want to know about the innovative “fuel-injector” like oil burner system we’ve developed for cutting your oil-fired heating costs. Since 2007, 90% of our users save a constant 20-28% reduction in their oil use, from before and as a result, our customers enjoy having a ROI (return on investment) of less than 3 years. No need to change your boiler!! Our patented technology also cuts harmful combustion emissions by up to 70%.

Many in the combustion field say; “It is one of the best innovations in oil heating technology in forty years”. This is made possible by a patented pressurized pump, catalyst element and heater process. Our system also includes a new modified burner, tested to UL Standards, which creates a much finer oil spray mist that greatly improves your systems’ combustion efficiency. This new technology doesn’t use the old efficiency methodologies. Our technology makes your existing heating system operate more efficiently than ever before and generates fuel savings for years to come and takes less than 2 hours to install.

The Burner Booster System is listed to all UL-safety standards and has proven itself over the last 6 years in improving operations and big fuel savings in: commercial and municipal buildings, manufacturing processes, apartment houses, Town-House complexes, college buildings and dormitories, mixed-use mill buildings, churches, and private homes. We also offer 100% equipment financing for most of our customers. We would like to meet with you, talk about our breakthrough system, and discuss how we can affordably make it work for your application.

In 2014 we became Advanced Burner Systems the product we launched would help Power plants of all type save on oil and fuel………..The larger systems using the Burner Booster patents platform became more advanced in saving of up to 30% in fuel usage operating costs. The 2 patents that were issued is 8,052,418 and 8,672,672.

Typical maximum efficient #2 oil heat burner flame at 1.28gallons per hour Rate, Combustion Flame Temp 1,485F. Carbon monoxide 12 ppm

The Burner Booster flame, same BTU heating oil at .87gallons per hour Rate, Combustion Flame Temp 1,875 F. Carbon Monoxide 0 ppm

These are Identical glass enclosed combustion chambers, both similar looking residential good quality oil Burners. The Right. is Boosterized!

Founder and inventor of the Burner Booster patented technology.

Agen’s Executive VP talking with a vendor at a national show.

Products in Action

Left Bottom - Typical Burn of No. 6 oil( bunker C.) maximum efficient burn; at 12.5gph Combustion Flame Temp 1,385F. Carbon-monoxide 92 ppm Right- The Burner Booster flame, same BTU heating oil at .87gallons per hour Rate, Combustion Flame Temp 1,975 F. Carbon-monoxide 6 ppm These are Identical glass enclosed combustion chambers, both looking in sight glass, with same camera setting.The Right is Boosterized!

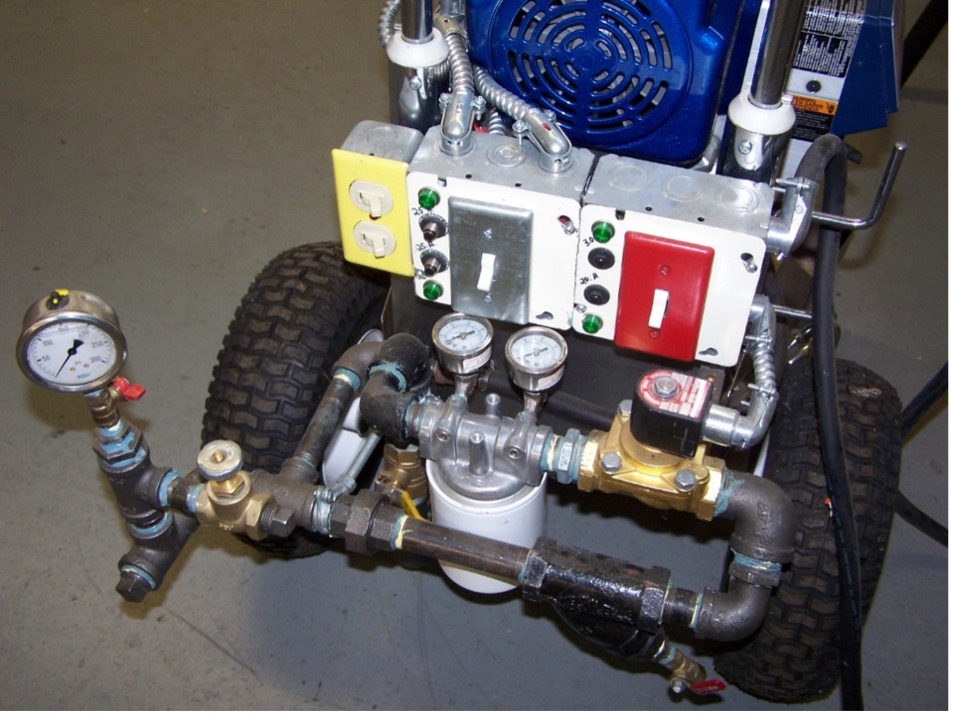

Below is a special system that can modulate and fire any of 3 fuels individually or all at one time. There is an option for Oxygen from the silver center nozzle. This was designed to be used in coal fire power plants. Test exceeded our expectations!

The Phoenix Burner Systems were designed to be duel or tri-fuel and modulate to save on total fuel costs by aiding better cleaner combustion in Bio-mass power plants, coal duel fired and oil-fired power plants. The burner nozzle adaptor has a nozzle for used oxygen gases.

Combustion flame temp was in excess of 2,500 F

This Photo is an actual live test showing 3 different fuels firing. One of which is #6 oil at 2.3 gallons per hour. One is waste fluid from biofuel processer at 1.8gph. and another fuel at .75gph of diesel emulsified with 20% water. The yellow hallo is real. The waste bio fuel has left over salt. This was the salt igniting.

During the process of producing Bio fuel provides a waste of one gallon for every 10 gallons produced. This waste often called “waste-crude glycerin is corrosive and very thick. This was our test site that worked so well the extra high heat melted the fire brick inside, validating temps reached over 2,250F.

This is the owner of Maine Standard Biofuels. He came to me because he was unable to burn this product, resulting in him paying to have it removed and burning his inventory product to keep his plant in operation.

This was our test site for a dual fuel system that could burn a water-based fuel! A liquid that is 25% water! And salt from the used discarded wasted vegetable oils he collected at restaurants.

Testing & Validation Reports

Advanced Burner Solutions

Needham Lab Multi Test Fuel

Emmissions Fuel Reduction CK EPA

CK Environmental

Sulfer Complete Oxidation

Brook Haven National Labs

Ledgeview Estates

Wayne Combustion Labs

Metro Matic Summary Comparison

WPI Results

Augustina

Testimonials

My Staff and the management board want to extend our thanks to your team and the Burner Booster System, as it has operated extremely well these last 12 months compared to the 2-4 lockout/shutdowns per week we experienced before. There were a couple of units we had with small leaking of about a table-spoon of oil per day under the box, a little speedy-dry was added, and then you made the adjustments.

Now for the AWSOME news your company has been waiting; we have saved over 1 full tank of oil, (7,200 gallons) fill-up, and that puts our saving at $24,500.-$26,000. FIRM compared to the past years average usage. The % saving with factoring in the coldest winter-spell points way north of 28% you were preparing me and my organization to expect. Our Calrin 1150 oil burner, which you boosterized, has proven to have been the most positive experience for keeping the operating cost down and reliability up in my facility.

I want to go on record to say we are more than grateful and very pleased, to have this relief from our operating budget. Sadly yet, the only one who believes we saved this much is the management, myself and accounting. It’s just too good to be true. Your guarantee of 15% or better or we get our money back sealed the deal. Well it’s kind of funny about the savings, we got more than our money back the first year in savings!!

Thanks again and Good luck.

Dan

Dear Eric:

I just wanted to drop you a quick note to say how very pleased we are with the results being

achieved using the two Burner Booster systems at our facility here in Rutland. This has been the best investment I have seen in my time here at Genesis in regards to energy savings. The

savings and service is nothing less than outstanding! But more important we don’t have the

smells from our boiler room and the boiler room is not half as hot and uncomfortable to be in.

I’m also impressed on how clean they both burn, it is great not to smell boilers running from when I get out of my truck to go into the building.

I have been tracking the savings on our boilers, (forced hot-water and one steam) and we are seeing an unbelievable savings in comparison of our past traditional usage. Savings on domestic hot-water fuel usage is over 25%. While during this entire heating season we are holding at a wonderful 27.2% savings; calculating for heating degree days.

I must admit many think the savings too good to be true, but I have a surplus in my heating

budget after taking on the coldest winter I can remember. I also want to thank your rapid

response in correcting and assisting on some issues that were non-Burner Booster related.

I hope my company expands its use of the Burner Booster in the other Genesis faciiities using oil.

Sincerely,

Robert Corey

Director of Maintenance Operations

Genesis Health Care

Rutland VT. Genesis

I have been tracking the savings on our boilers, (forced hot-water and one steam) and we are seeing an unbelievable savings in comparison of our past traditional usage. Savings on domestic hot-water fuel usage is over 25%. While during this entire heating season we are holding at a wonderful 27.2% savings; calculating for heating degree days.

I must admit many think the savings too good to be true, but I have a surplus in my heating

budget after taking on the coldest winter I can remember. I also want to thank your rapid

response in correcting and assisting on some issues that were non-Burner Booster related.

I hope my company expands its use of the Burner Booster in the other Genesis faciiities using oil.

Sincerely,

Jamaine Kaltas

President Founder

To whom this may concern,

In November 2013 we purchased two Burner Boosters (BB). One BB was installed in a Northern Armory in Houlton, Maine with an average of 7,175 Heating Degree Days (8,387 HHD for 2013-2014) and the other BB was installed in a southern Armory in Sanford, Maine with an average of 7,000 Heating Degree Days (7,895 for 2013-2014).

We are pleased with the savings in both locations. In the Sanford Armory we saved approximately 2,500 gallons of fuel oil (20% savings) and in Houlton we saved approximately 6,650 gallons (36% savings) based on our seven year average fuel consumption for both facilities.

We did experience a few technical issue throughout the heating season, although none were insurmountable. In Houlton the main issue was non-response from the contractor who won the bid. They were certified by Burner Booster as a reseller/installer, but as we all found out they did not have a oil burner mechanic on staff and was over 250 miles from the site. Therefore, we had our in-house Maine Army National Guard burner technicians from Augusta respond (~200 miles one way) with Eric Lavoie to correct the burner/flame issues. Eric made the necessary modifications to the BB in Houlton to our satisfaction. In Sanford, Eric also respond to a couple burner “no heat” issues one being a transformer issue and the other a stuck pressure gauge which had nothing to do with the BB. In the later case Eric “walked” the sergeant on site through a troubling shooting procedure that identify a stuck pressure gauge that was subsequently repaired by the Maine Army National Guard.

Going forward, we are currently evaluating the potential of Burner Boosters in other facilities. We will have a tighter scope of work that will require a Maine qualified burner technician to install any future Burner Booster along with required subsequent service calls two and four weeks after install and monthly thereafter for the winter season concluded by a shut down and cleaning and they will have to be able to respond within an half hour.

Our projected savings that was used for our pay back analysis for the two Burner Boosters was based on an estimated savings of 15% or approximately 4,500 gallons.

We exceeded the initial estimate by over 100% with over 9,150 gallons of fuel oil which equated to 30% savings between the two Armories during one of the coldest winters over the last 10 years. Again we are pleased with the savings and we are currently evaluating the potential of Burner Boosters in other facilities.

Best Regards,

AJ Ballard, C.E.M.

Maine Army National Guard

Energy Manager

Building 8, DFE

Augusta, Maine

207-430-5679

To Whom It May Concern,

My name is Jon Harbison and I am the General Manager for Harbison Plumbing, Heating and Air Conditioning, Inc, located in Houlton, Maine. I am writing this letter in reference to the Burner Boosters we purchased from your company in the spring of 2013. We purchased four Burner Boosters that we installed in two separate buildings in two schools in Hodgdon, Maine. Two boosters were installed in the Hodgdon High School and two in the Hodgdon Elementary School.

Throughout the 2013-2014 heating season, we kept in close contact with the school bookkeeper to see how the fuel savings were compared to previous heating seasons. The results have been surprising and very favorable. The final figures have not been tabulated, mainly because we live in Northern Maine and we just shut down our heating systems. The school has reported to their Board of Directors that to date, they have saved somewhere between 38 – 48% over last year. This is due exclusively to the installation of the Burner Boosters. Nothing else was changed to either building that would contribute to fuel savings. might also add that this past winter was the toughest winter we have seen in 20 plus years. In our current economy and continued constraints on Public School budgets and cuts, this is a very welcomed savings to the Hodgdon School district.

Our company did experience a few technical problems with the Burner Boosters, but nothing we were not able to correct immediately or with any expense to the school. We would also add that Eric Lavoie’s assistance with these mechanical failures was immediate and without hesitation. Eric, on several occasions, dropped everything to travel hundreds of miles to help us out and stand behind his product. We can’t thank him enough for that. During these mechanical failures, the buildings were at no time without heat. Both buildings have dual boiler arrangements and one boiler carried the load while we fixed the malfunctioning unit. Most of the failures were in ordinary burner parts and not necessarily the Burner Booster Box. Eric also supplied us with a complete Burner Booster Box along with some spare burner parts specific to the burner that we were having trouble with. Eric was well aware of the climate that we live in and the urgency to revive a heating system when it goes down. Thank-you Eric from our company and the Hodgdon School District.

In closing, the Burner Boosters installed easily, with Eric’s guidance, their “Return on Investment” will be less than the projected 2 ½ year payback time frame, and our customers are happy, VERY HAPPY. We were challenged at the outset with some very doubting Board

Members and local citizens who really questioned whether or not they would see the kinds of savings we were projecting. We left them with their “jaws on the table” when we reported the results. Keep up the good work Eric and your associates, and keep on developing more energy efficient equipment.

Dear Eric,

White Mountain Oil could not have been more pleased with the performance and the savings after the first year at Deer Park Recreation center. As a result of their condition to hire us if we could save them on oil, was a winner for all.

The 5,600sq ft. Recreation Building had 2 very good performing Carlin 802CRD Burners, on

Burnham boilers; showing a combustion analyzer efficiency reading of about 83%. Their

records and ours, based on the previous year with heating degree days, has shown on the

shoulder of the season to be about 15% fuel oil savings and then during the peak of the winter a solid 18-20% fuel oil savings. The system was installed back in September and since then; not one time out, lock out or safety-lock out. The Boiler room is a lot cooler too.

The recreation center management staff has mentioned several times to us that this was totally unusual not to have the heat go down. We have some other potential customers we would like to get the Burner Booster installed at this summer. It has been a real winner for growing our

reputation and adding some new accounts.

Thanks again, hope you and your staff have a great season,

Sincerely,

Bob Morin

Service Manager

Dear Mr. LaVoie and your staff,

Our biggest thanks to you, and the Burner Booster; as it has exceeded all our expectations. The elimination of all odors from our large boiler room is a true testimonial all to itself on the clean burning of 28gph before and the 16gph which is equating to be saving a reduction of 70 gallons per day on the colder days with the Booster system. Our fuel saving to us is drastic, especially in this hard economy to show an average savings just north of 30%WOW! The slightly quitter operation is a plus.

Our mill plant doesn’t have½ as bad steam controlled heat issues as before-Love to know how you did that!! I was so use to 2-3 complaints a day from burning our oil with the uneven heat and odors, that now I can now focus more of my duties managing my property and operations.

Again, thanks for the added effort and quick install. I’m totally gone from skeptic to now I’m offering you and your company space at my mill if you need to expand. If I learned anything, is that I should have put the Burner Booster in September and not waited, the mill would have saved sooner.

Richard J Bruno

Property Manager

This is an update on our experience with the Burner Booster over the course of this heating season just ended.

Based upon degree day compensation, we have experienced fuel savings of roughly 31% as compared with the heating season of 2010-2011. Those results are remarkable, and provide for an ROI over less than two years.

We at Acme Staple would recommend the equipment to any user spending (at current prices) $10,000 or more since the savings would likely be in the $3,000 range and provide a ROI of 36 months or fewer. That’s a pretty good investment.

I grew up in the heating business, and, in fact have owned a retail fuel business. I cannot recall an improvement in equipment and process which has shown as much promise as yours shows. This technology has legs in my opinion, and clearly should be considered by any volume user.

Regards,

Acme Staple Company

General Manager